What are Tolerances?

We all have our own personal levels of tolerance: just how much we are willing to accept before actions need to be taken. The lines drawn will look different for everyone. For instance, there are days where I’ve reached my maximum allowable amount for nonsense and then it’s game on. People, aka: family, friends, clients, and strangers (because I’ve still got that New York in me…) will be politely, but directly, told they are being a pain with carefully chosen wording, and then *hopefully* a reset occurs. I know you feel me on this!

Tolerances within the garment industry work along a similar line. There is only so much that is allowed to occur before actions are taken and inconsistencies are put to right. Now don’t get me wrong, tolerances aren’t a law that must be followed and only one party benefits, nor are they intended as an “or else” statement. Tolerances are guidelines put in place to protect everyone.

Garment Industry Use of Tolerances

Tolerances are defined amounts of deviation from a specific agreed upon standard. In other words, tolerances specify exactly how much different something is allowed to be from what was agreed upon. They exist in all sorts of facets in garment production. There is tolerance for the amount of shrinkage allowed on fabrics you order. There are tolerances for color variations. There are even tolerable amounts of garment torquing from a wash test. Basically anything that can be standardized, tested, or verified is allowed a specific amount of deviation.

For the purpose of this blog post, and to stay within the scope of my knowledge base, I’m doing the dive into tolerances for garment measurements in a production setting. This is something that you will definitely want to be aware of and utilize for your own workflows because it will ensure that everyone you work with is on the same page as you.

Why do we use tolerances?

We’ve already discussed that tolerances allow a certain amount of deviation. But the reasoning behind them is that when human hands are a part of putting something together, it will be almost impossible to maintain 100% consistency for every single product.

Let’s say that you have a t-shirt that is being sewn in a factory and the machine operator who is responsible for sewing the side seams starts off the day a little sluggish. They are tired and just getting warmed up for the day, so they may shave off an extra 1/16” per seam as they join the front to the back. Automatically, this makes the garment full circumference ¼” smaller than the master pattern it was cut from. An hour into this sewers shift, they are on fire and getting nearly every seam they sew spot on. But the closer they get to the end of their shift, the more tired they are and the amount of seam allowances they take can be even more. Maybe they are shaving off 3/16” per seam, which equals out to ¾” total circumference. As you can see, there is variation in measurements throughout the day.

If you’ve ever had to do the same repetitive task all day long, like this sewer, you will know that this is a completely understandable situation. We are humans, not machines, so our work will always be imperfect. In garment production there are so many variables that can affect the final product.

How are tolerances communicated?

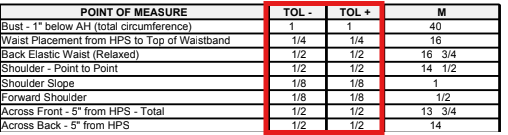

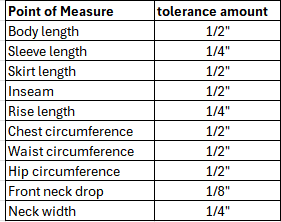

Tolerances are generally listed on the graded spec page of a tech pack as a fraction amount that is allowed for deviation.

They can also be listed on the product development page so everyone is aware, but generally tolerances given at the product development stage are a guideline because sometimes to make the fit work, the pattern maker needs to go beyond the measurements given.

How Much Tolerance?

By now you are probably waiting for me to give you the magic numbers. Now, to be clear, these are a general guideline and every brand will do them differently for different reasons as their brands grow.

For body circumferences, I like to stick to 25% allowable difference. For instance, your t-shirt comes in small, medium and large. There is usually a 2” difference between each one of these sizes. 25% of 2” is ½”.

Tolerances are not specific to certain sizes. What I mean is that even if your t-shirt has an XL and an XXL with a larger increment between sizes, we will still stick to that ½” for all sizes. This is done because in a mass production environment quality assurance is not going to remember that for XL sizes, there is ¾” tolerance. Yes, this would make things much more fair for the factory. However, unless you are dealing with thousands of t-shirts, chances are no one will fight you on this.

Assigning Tolerance Standards

In general, you can only give tolerances if you are providing garment measurements. If you are just sending a pattern to a factory and telling them to go for it, then you have no recourse for any deviation from the original pattern. Tolerances need to be given with finished garment measurements because these measurements define what the standard is.

As for who determines the tolerance, that generally falls under your brand specifics and the same tolerances will be applied to every single garment. Tolerances usually do not vary from style to style unless there are specific features that require a new tolerance to be set.

Your pattern maker can help you determine if you are unsure. A technical designer can as well. But it also comes down to your point of view as a designer. Let’s say you have a very specific collar shape that you want to achieve. The measurement has been defined and your tech designer says that tolerance should be ¼”. You may feel more comfortable with ⅛” because anything more or less than that amount will yield a different looking garment.

Being Realistic About Tolerances

I encourage you to have tolerances in place for your business, but keep them loose. If you are only producing garments, maybe 20-50 pieces at a time, no one at the factory is going to measure every single one of your garments to ensure it meets the allowable tolerances unless they have people with lots of free time, or they are just gold star amazing and this is part of their workflow.

Factories crank out garments. That’s it. They aren’t invested in your brand and your customer fit experience. They do not care about maintaining all necklines that fall within a ⅛” tolerance, or if a body length is ½” shorter from standard if you are producing 20 pieces. When assigning tolerances, put yourself in the factory's shoes. Would you want to hear from some start up designer, who is doing their first production, that they don’t want to pay you because a pocket is ⅛” smaller than it should be?

But having general tolerances in place protects your investment. For example, I had a client that produced hoodies. They only wanted the patterns from me. Tech packs were non-existent and they didn’t want to trouble their factory with them. But then the factory produced the hoodies and the client was mad because they felt like the sizing was off. They sent me garments to review, and sure enough, some were 1” smaller, some were 2” bigger and very few garments measured exactly what they should for the core body widths. There was nothing to be done at this point and they chose to sell these inferior products to their customers.

In this situation, this amount of difference is really unacceptable regardless of how big your order is.

Recourse for out of Tolerance

This is where you pick your battles. Big brands really enforce tolerances. There are entire quality assurance teams and inspectors that visit factories. But most likely this is not where your business is at, so let’s discuss how tolerance considerations would play out for you.

You have two main considerations:

Is the measurement that is out of tolerance one that would change the look of the garment, or the overall fit. (Usually, I’m only concerned with tolerance for chests and hip circumference)

Is the garment out of tolerance enough to make it a different size? This is problematic as it may affect whether or not your customer chooses to return.

If you find that one of these is problematic then you can choose to bring it up to the factory and ask them to fix or accept as is, knowing that this changes the agreed upon outcome.

What it means to push back if something is out of tolerance

I don’t want to give you the wrong idea that tolerances are a contract protecting you from a factory’s shoddy work. Not at all! If anything, tolerances provide a guideline so the factory can be aware and monitor potential deviations.

Let’s say that your sleeve length is out of tolerance in the finished product that was shipped to you. It is ½” longer than you wanted. If you really wanted to stick to your guns you would ship this package back to your manufacturer where they would begrudgingly fix it for you. The thing is, alterations after production are not part of the factory workflow. More than likely fixing your sleeves will take them 3 times longer than making the garments and they have to stop or delay other projects in work. From this point, chances are they won’t work with you again unless you are giving them really large orders. You aren’t worth the effort going forward because you are going to give them a hard time.

In the case of the client with the hoodies, if it were up to me, I absolutely would have gone back to the factory and had them remake. This was just sloppy work and it was allowed to happen over and over again.

Tolerances can help both you and your factory, but it’s important to understand the implications and how to yield their power when needed. If you find that variations occur after shipment, then it is worth a conversation about quality standards, but just don’t give your factory a hard time! Most of them are trying their hardest and can make modifications going forward once they fully understand what your standards are.